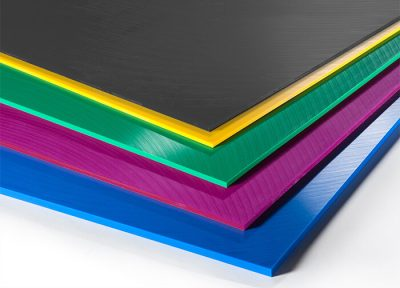

Product introduction

What are the benefits of using HDPE board?

HDPE sheets are popular for a number of reasons. The most important advantages of HDPE sheets include:

Resistance: HDPE sheets are highly resistant to chemicals and impacts, in addition to being resistant to rust, rot, insects, mold and mildew.

Longevity: Due to HDPE's high chemical, weather and impact resistance; it can outlast most conventional materials.

Durability: The durability of HDPE while being light is one of the most important factors in its popularity.

Weight: As mentioned above, HDPE is known for being the perfect combination of lightness and durability. That's why you'll see it in everything from children's toys to chemical tanks.

Malleability: HDPE sheets can be quickly and easily molded into almost any shape. Thus, forming/converting can be done at the factory or on site (usually as part of repair work).

Weather Resistance: HDPE sheet is used in a variety of outdoor applications and can withstand some of the most extreme weather.

Sustainability: In addition to all the advantages mentioned above, HDPE sheets and products are easy to recycle.

How to bend HDPE sheet?

Use a bending machine to heat the HDPE sheet to 50-60°C for about 20 minutes, and use a bending machine to bend it to the desired angle. Note: If the temperature is too high, it will easily damage the surface of the HDPE sheet, and in our test, it takes about 20-30 minutes for the HDPE sheet with a thickness of 10mm.

Will bending the sheet damage its structure?

If the sheet is thicker than 10 mm, there may be some deformation on the sides of the sheet due to compression of the material inside the radius. This can be solved by making a half cut along the curved edge to reduce the amount of material compressed. To achieve a good bend, hold the workpiece in the desired position until the sheet cools down. If the sheet is heated properly it will hold its shape.

Related Products

If you need our products please write down any questions, we will reply as soon as possible.